Have you ever tried to loosen a rusted bolt in a cramped engine bay, only to have the penetrant miss the target and soak everything except the part you actually wanted to hit? I’ve been there. In my years of working in automotive maintenance, I’ve realized that messy overspray and wasted fluid aren’t just annoying—they don’t get the job done. And it’s a waste of money.

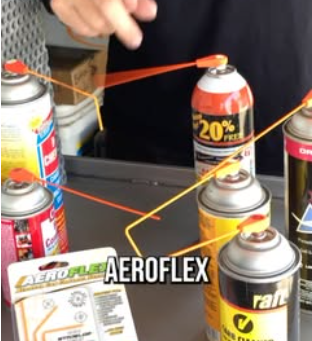

When I developed Aeroflex, there was nothing to compare it to. There was no blueprint to follow. It was a shot in the dark that worked in a big way—because nothing like it had ever been on the market before. Something had to change. While traditional automotive aerosol products get the job done, controlling the flow of those products was the problem. That’s why I created Aeroflex.

The Aeroflex Aerosol Can Control System was designed to solve this exact problem. This system turns a standard aerosol can into a high-accuracy specialty tool.

What are the benefits of Aeroflex Straws

Critical mechanical parts—like seized fasteners, window regulators, or throttle bodies—are often are hard to reach or even tucked behind fender panels and heat shields. Reaching them requires more than just a straw, that’s where the Aeroflex Pro-Shot Two in One angled straws come into play.

- Easability: Often lubricants will splatter onto sensitive surfaces. Like brake rotors or drive belts. Our angled straws help mitigate the spatter or over spray.

- Contamination Control: In high-stakes environments like aviation maintenance or precision engine builds, keeping fluids localized is a matter of safety and performance.

- Zero Waste: Our straws help to ensure the product reaches the targeted area, this preventing waste. Saving you time and money.

The Little Red Straw

We all know the little red straw taped to the side of the can. We also know, that these straws will often dislodge from the nozzle. In a busy shop, they’re easily lost. And when a straw pops off mid-spray, you’re left with a puddle of wasted chemical or even worse a face full of overspray. The Straw Loc works with both the little red straws and aeroflex straws.

The Aeroflex System: Step-by-Step Precision

The system uses patented mechanical retention to ensure the straw stays put, even under high-pressure bursts.

- The Straw Loc: Slide your straw through the Straw Loc before pressing it into the nozzle orifice. This patented design guarantees the straw is locked once and for all.

- Pro-Shot Straws: Configure for the Task. Use the Pro-Shot Straws (available in 45° and 90° angles) to reach around past and through steering linkages, behind grills or any hard to reach spots.

- Execute: With a rigid, leak-proof connection, you can apply penetrants or cleaners with pinpoint accuracy.

- Power-Grip Connectors: Our connectors create a secure connection when linking two straws together for extended reaches.

Aeroflex is used by professionals across the most demanding fields, from automotive shops to aviation hangars to professional racing pits and heavy equipment maintenance.

All Aeroflex products are made in the USA. This commitment ensures that each item is made with quality every time.

Final Thoughts

In any professional mechanical environment, a lot depends on the reliability of your tools. The standard straw cannot compare to the quality that Aeroflex products provide.

By switching to the Aeroflex Aerosol Control system, you are moving beyond a simple friction-fit accessory to a mechanically locked, industrial-grade solution. With the combined power of theStraw Loc and the Power-Grip Connector technology, you eliminate the mess of overspray and the safety risks of fluid contamination. It is an investment that ensures your focus remains on the job at hand, not on chasing a lost straw across the shop floor.

FAQ’s

- How do I stop my straw from falling off?

Use a Straw Loc. It mechanically secures the straw to the nozzle, preventing dislodging even under high pressure. - Can I customize the lengths?

Yes. Aeroflex Pro-Shot Straws can be cut with a utility knife to fit your specific reach requirements. - Will it fit my can?

The system is designed to fit 90-95% of standard automotive aerosol products on the market today. - How does this system help reduce shop costs?

Precised application significantly reduces “overspray”—the product pinpoints the target – saving cost. - Is the system reusable, or do I replace it with every can?

The Aeroflex system is a professional tool, not a disposable accessory. Once a can is empty, simply move it to the next can.